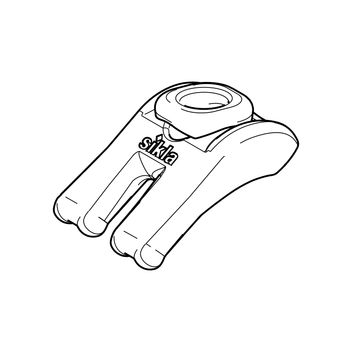

Beam Clip SPA 5P AU HCP

Application

Universal clamping element for all load bearing end plate and channel connections to existing steelwork without welding or drilling.

Scope of delivery

Beam Clip 5P with support plate AU

Installation

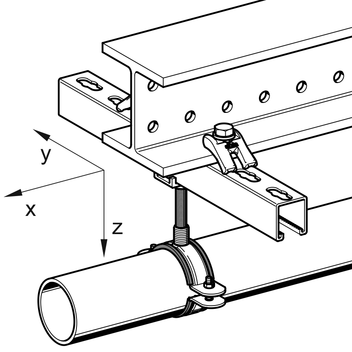

Position the Beam Clip so that the slit side of the clip is in contact with the connecting part and the head of the clip against the existing (primary) steelwork to which the assembly is being fastened. Insert the hex bolt and tighten hex nut to the required installation torque.

The rounded support segment of the Beam Clip ensures that a form-fit contact is produced which prevents shifting or bending stress. Therefore a continuous Beam Clip preload force is ensured.

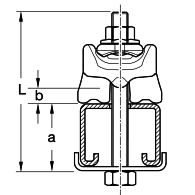

Determination of the required screw length Lmin:

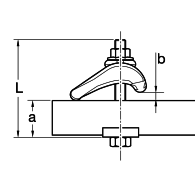

Arrangement A

Hexagon bolt with Holding Bracket

|  |

| M12: Lmin = a + b + 49 [mm] M16: Lmin = a + b + 59 [mm] |

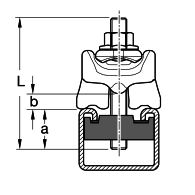

Arrangement B

Inserted T-Head Bolt HZ

|

| M12: Lmin = b + 55 [mm] M16: Lmin = b + 65 [mm] |

Technical Data

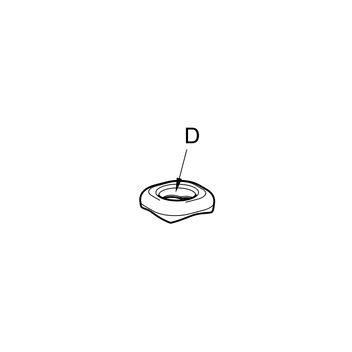

| Type | Clamping range [mm] | B [mm] | L [mm] | D [mm] |

|---|---|---|---|---|

| M12 AU | 1 - 30 | 44 | 60 | 13 |

| M16 AU | 4 - 40 | 48 | 72 | 17 |

| Type | Tightening torque MA [Nm] / plus 90º revolution | Fz permitted per Beam Clip [kN] 1) | Shear force load capacity Fx per 2 Beam Clips [kN] 2) |

|---|---|---|---|

| M12 AU | 60 / 90° | 16.2 | 3.7 |

| M16 AU | 140 / 90° | 19.5 | 4.2 |

| 1) | The specified data relate to the application of a standard hexagon bolt with strength class 8.8. |

| 2) | The specified data relate to the worst case with flange thicknesses 30 mm (M12) or 40 mm (M16) as well as a coefficient of static friction µR = 0.20. A possibly operating tensile force Fz isn't included. |

| Material: | Steel, HCP |

Approvals / Conformity